PRODUCTS

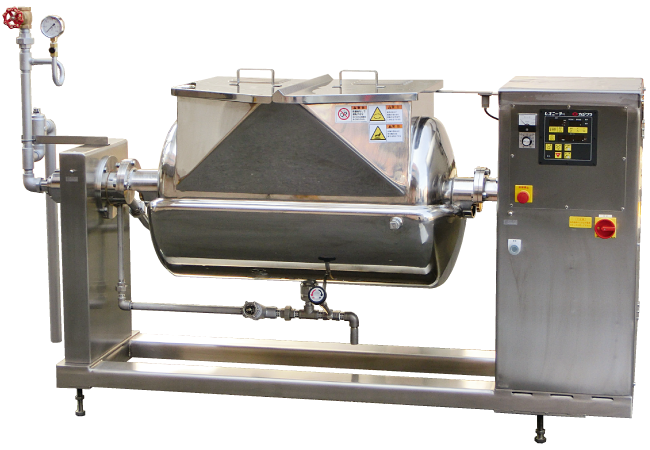

Reokneader KH

Steam

Basic machine for all rounded production support.

Kettle capacity

50~4,000L

FEATURES

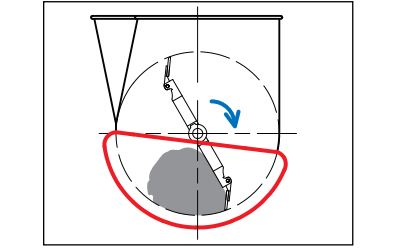

01 Jacket structure aligned to a dynamic plane

●With jacket structure that is aligned to the dynamic plane as shown in the figure, heat exchange for heating/cooling can be performed evenly, which prevents scorching and results in consistent products.

●Large heat transfer area increases the temperature quickly, which increases the productivity per batch and delivers superior cost performance.

02 Steam heating

●Has superior safety compared to gas heating due to centralized management of heat source and ease of maintenance.

●Max. Steam working pressure of up to 0.3MPa makes it suitable for high temperature cooking (also capable of handling high pressure steam).

03 Stainless steel finishing

●All stainless steel finishing imparts superior durability, which makes it easy to clean and hygienic.

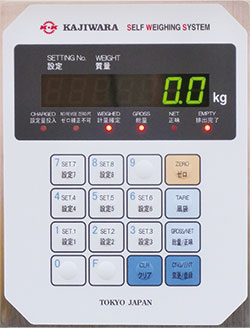

04 Measuring devices

●Product temperature sensor/timer come as standard installation.

●Kettle temperature sensor (option) is also available for measuring the kettle surface temperature in order to manage the heating temperature by numerical value to prevent scorching.

●Self weighing system (option) is a device for controlling the cooking process by weight. With this, you can obtain consistent products without variations between batches.

05 Designed for safety and hygiene

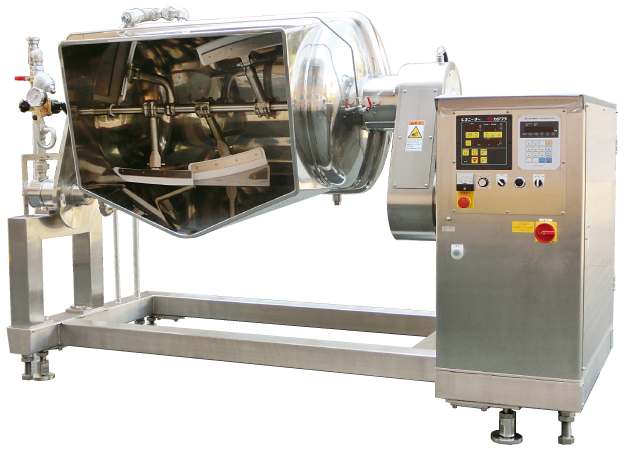

06 Kettle bottom outlet valve (option)

●Smoothly unload ingredients without any leftover.

USES

Various type of bean paste, Jelly, Jam, Marmalade, Custard cream, Fondant, Filling, Stew, Roux, Various Japanese dishes (Tsukudani, Denbu, Kinpira), Cream croquette, Peanut cream, Sauce, Soup, etc.

SPEC

| Model | KHS-1E | KHS-2E | KHS-3E | KHS-5E | KHS-6E | KHS-8E | KHS-10E | KHS-15E | KHS-20E | |

|---|---|---|---|---|---|---|---|---|---|---|

| Kettle capacity (L) | 110 | 230 | 300 | 500 | 620 | 840 | 1,210 | 1,670 | 2,440 | |

| Power supply | 3Phase 200V/380V/400V | |||||||||

| Mixing motor (kW) | 0.75 | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | ||||

| Max. Steam working pressure | 0.3MPa | |||||||||

| Steam consumption(initial/average)(kg/h) | 120/90 | 190/130 | 220/150 | 310/210 | 340/240 | 410/280 | 530/370 | 640/440 | 750/520 | |

| Kettle tilting (kW) | 0.2 | 0.4 | 0.75 | 1.5 | ||||||

| Dimensions (mm) | Width | 2,310 | 2,610 | 2,760 | 2,980 | 3,095 | 3,555 | 3,830 | 4,405 | 4,695 |

| Depth | 815 | 890 | 945 | 1,045 | 1,125 | 1,240 | 1,935 | 2,195 | 2,415 | |

| Height | 1,445 | 1,545 | 1,590 | 1,670 | 1,850 | 2,230 | 2,260 | |||

※Other dimensions are available on request. Other specifications than specified above are also available.

※Above specifications may be revised for the technical improvement without prior notice.

※This product is made in Japan.

LINEUP

-

Reokneader KH-FT(Front tilting type)(Steam heating)

- Power Supply :

- 3Phase 200V/380V/400V

- Heat Source :

- Steam

- Kettle capacity :

- 300~620L

-

Reokneader KHF(Gas heating)

- Power Supply :

- 3Phase 200V/380V/400V

- Heat Source :

- Gas

- Kettle capacity :

- 200~500L

-

Reokneader KHV(Vacuum type)(Steam heating)

- Power Supply :

- 3Phase 200V/380V/400V

- Heat Source :

- Steam

- Kettle capacity :

- 50~4,000L