PRODUCTS

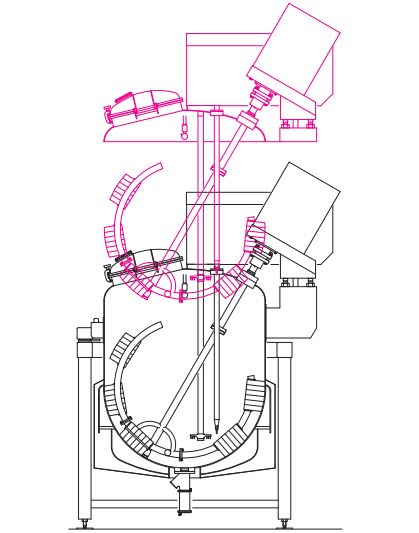

Oblique Axis Mixing Cooker OAM

Steam

All-in-one Batch. Pre-Mixing is no need.

Kettle capacity

80〜10,000L

FEATURES

01 Even mixing in a shorter time by oblique mixing.

●Combination of the oblique axis & the semi-spherical kettle achieves effective mixing in both vertical & horizontal directions.

●Oblique axis produces even & stable quality without damage to the characteristics of the food texture.

02 Structure for easy cleaning with no shaft seal & no collected bacteria.

●No screws inside the kettle in addition to the overhead oblique mixing with no shaft seal & no collected bacteria.

●No falling bacteria from above by the totally closed structure.

●Superior sanitation to meet HACCP.

●Products discharge valve at the bottom can be dismantled and cleaned very easily.

03 Automatization of All-in-one-batch production promotes labor saving & full automation.

●By using options, many processes from weighing to cutting, smashing, grinding, kneading, diffusion, etc, can be totally carried out.

●Programmed control manages improvement & stability of the product quality and achieves many-kind & small-quantity production and drastic labor saving & full automation.

●Model OAM is a space saving machine that enables remarkable cost performance in production quantity per machine setting space.

●Combination with Food Dumper (right picture), pump, etc, achieves automation of the front-side & the back-side processes.

USES

●Various seasoning, Sauce, Curry roux, Soup, Grary sauce, Mayonnaise, Dressing, Miso, Jam, Flour paste, Other Paste foods, Fried foods, etc.

●Heating and mixing of chemical industry products – cosmetics, oils, etc.

MOVIES

SPEC

| Model | OAM-6 | OAM-8 | OAM-10 | OAM-15 | OAM-18 | OAM-23 | OAM-28 | OAM-40 | OAM-60 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Kettle capacity (L) | 590 | 800 | 1,040 | 1,500 | 1,870 | 2,290 | 2,780 | 4,020 | 6,020 | |

| Power supply | 3Phase 200V 50Hz/60Hz | |||||||||

| Mixing motor (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | |||||

| Main shaft rotation speed | 8~25r/min | |||||||||

| Max. Steam working pressure | 0.3MPa | |||||||||

| Steam consumption (kg/h) | 210 | 260 | 290 | 370 | 410 | 470 | 530 | 660 | 820 | |

| Kettle bottom valve size | 2S | 3S | ||||||||

| Dimensions (mm) | Width | 1,405 | 1,505 | 1,605 | 1,755 | 1,855 | 1,955 | 2,060 | 2,150 | 2,650 |

| Depth | 1,400 | 1,485 | 1,555 | 1,775 | 1,835 | 1,870 | 2,005 | 2,330 | 2,650 | |

| Height | 2,205 | 2,305 | 2,410 | 2,795 | 2,895 | 3,320 | 3,425 | 3,600 | 3,800 | |

※Other dimensions are available on request. Other specifications than specified above are also available.

※Above specifications may be revised for the technical improvement without prior notice.

※This product is made in Japan.